Manufacturing Automation: What Is It?

Types of Manufacturing Automation

Fixed Automation

Programmable Automation

Flexible Automation

Examples of Manufacturing Automation

Fixed Automation Examples

- Assembly lines with automation

- Methods used in the manufacture of chemicals

- Conveyor systems for material handling

- Production lines for machining

- Automation procedures for paint and coatings

- System conversion and handling on the web

Programmable Automation Examples

- Machine tools that are numerically controlled

- Controllers for programmable logic

- Commercial robots

- Manufacturing of frozen foods

Flexible Automation Examples

- Welding Arc

- Spot welding

- Material handling

- Machine tending

- Painting

- Assembly

- Mechanical processes such as cutting, grinding, deburring, and polishing

- Gluing, adhesive sealing, and spraying of materials

Industries Making Use of Manufacturing Automation

Automotive

Pharmaceuticals & Medical Devices

Food and Beverages

Products for Consumers

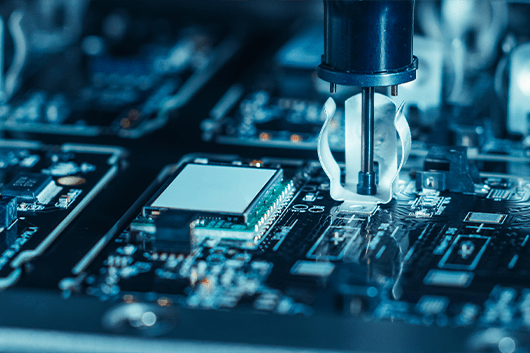

High Technology & Electronics

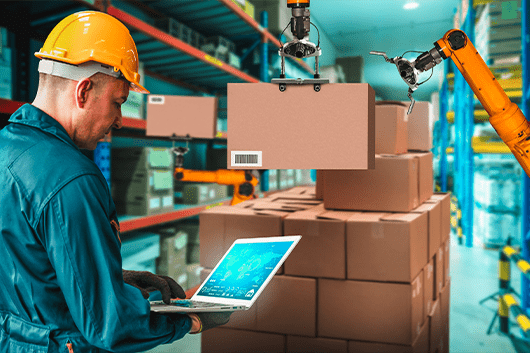

Packaging

Advantages of Manufacturing Automation

Cut Down on Production Time

Reduced Risk and Human Error

Help and Skills Mitigating Labor Shortages

Improved Tracking of Production and Analytics

Key Developments in Manufacturing Automation for 2023

Improved Connectivity with 5G

The advent of 5G promises expanded coverage, improved connectivity, and faster download times. In 5G-enabled plants, up to 30% production gains are expected, accompanied by remarkable improvements of 90% in defect detection and 50% in assembly time.

Industry-Specific Internet of Things (IoT)

The growth of IIoT is anticipated to be a significant development in the upcoming year. By linking several "smart" devices with cutting-edge sensors and automating and optimizing the production process, IIoT boosts productivity multiple times over. Note that the growth of IIoT and robotics necessitates large network bandwidth; therefore, connectivity capacity may be necessary.

Artificial Intelligence

The anticipated rise of AI is expected to impact the manufacturing industry significantly. AI applications extend to various areas, including production lines, supply chain management, and commercial operations. In the coming years, the main focus of AI applications is likely to shift towards supply chain management, goods, and services, which currently are concentrated on intelligent production.

Skilled Workers in the Age of Automation

Due to the rapid development of technology, workers must acquire new skills and transition away from outdated knowledge that can now be performed by automation.

Human employment is becoming less necessary in specialized fields such as Augmented Reality (AR) and Virtual Reality (VR) technologies. For instance, these technologies can aid in understanding the production of goods that might ultimately end up in hazardous or hard-to-reach places, such as space stations.

As digital twins become more intricate and valuable, the demand for individuals with knowledge and expertise in this area will rise. A digital twin is an electronic duplicate of an actual process that can be utilized to comprehend and enhance production lines and outcomes.

Experience the Future of Manufacturing with Smart Factory's IoT Integration

The Future Role of Automation in Manufacturing