Downtime is any period or the total amount of time during which a process is not active. Please note that not all downtime is the same, and it can be divided into two types: planned and unplanned.

Planned production downtime occurs when production schedules a period to shut down the process. During planned production downtime, the machines are usually maintained through inspections, cleanings, and part replacements.

Planned downtime allows operational planning, scheduling, and preparation. While the process is down, staff can organize tasks to be completed, order parts, and communicate with stakeholders. Planned downtime can be set up to ensure that staff members have specific tasks to perform and all the required resources and tools are available at their disposal.

Unplanned production downtime occurs when a machine or process is unavailable due to an unforeseen circumstance. An unplanned downtime can occur due to a component breaking, running out of supplies, a power outage, and so on. Unplanned downtime events are unpredictable, therefore, you should focus on managing them in a better way to minimize the overall downtime cost.

Unplanned downtime tends to be more expensive and hazardous than scheduled downtime. Since unexpected downtime does not occur with a warning, there are many potential causes for the production process to stop, and preparing for every potential issue is impractical.

If components or the appropriate staff are not available when a problem arises, the machine may not operate for a longer period of time. Longer downtime means less time spent on producing goods, that has an immediate negative impact on profitability.

Wasted material and unsellable goods are additional expenses linked to unplanned downtime. Poor quality output is typically produced just before, during, and after the process shuts down and restarts.

Additionally, unplanned downtime may result from mishaps or near misses. During unforeseen downtime, the objective is to restart the machine or process as quickly as possible. During such an urgent scenario, people may get panicked and respond inaccurately rather than pause to consider the best course of action, leading to a stressful and chaotic workplace environment.

Minimizing unscheduled downtime can decrease overall manufacturing downtime costs. It also lessens the amount of time workers are put in erratic circumstances, reducing the risk of accidents.

Manufacturing downtime may occur for several reasons, so it becomes imperative to use various strategies to minimize them in the workplace. Some of these strategies are;

It’s crucial to track downtime before taking any action to minimize it. Monitoring downtime gives you an insight into why the process is failing and helps you understand the overall performance of the process.

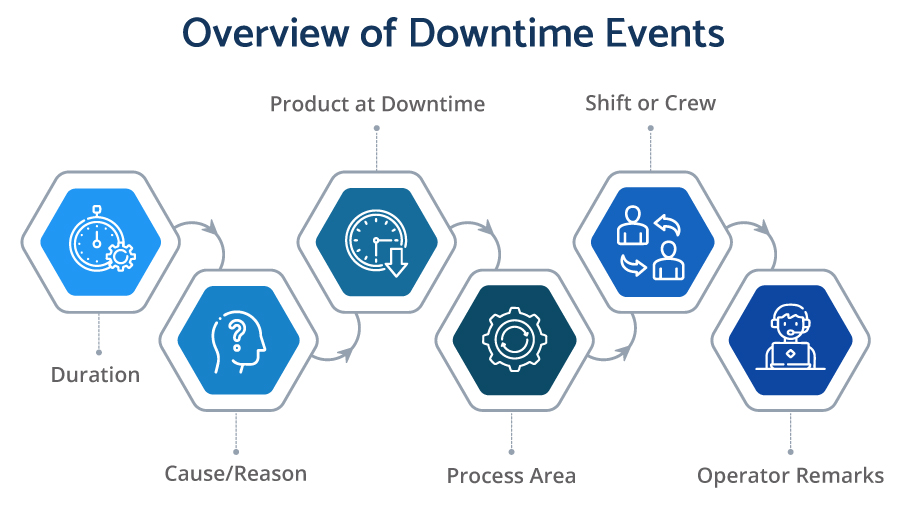

For every downtime event, you should collect the following information:

Using the compiled information based on historical data can provide you a clear idea of where how, why and even who might be the possible root cause of downtime. This allows you to make plans or changes based on predictive analysis, thereby preventing, limiting or avoiding future downtimes.

Additionally, you should consider collecting data on waste accumulated over time, safety issues, environmental events, and so on.

Early Warning With Continuous Downtime Alerts in Production Tracking

A system to monitor production can also help reduce downtime. Operator stations with visible process trends can see how the process is operating over time and track whether factors change or remain static.

Alarms can alert operators about any unbalanced conditions either on their own or in combination with dashboards and trends. This might enable them to respond faster and possibly avert a downtime event.

Make a Schedule for Preventive Maintenance

Preventive maintenance is carried out while the process is in operation or during scheduled downtime. Replacing a part during scheduled downtime saves time and the cost of downtime in manufacturing by enabling the site to order the appropriate parts and ensure that the right people are present to complete the duties.

The parts can last longer if regular maintenance is performed while the process is in operation, such as cleaning and lubricating oil additions or changes.

A schedule can be monitored to ensure tasks are completed on time. If a task is missed, an operator reminder or a supervisor alert can be sent. By documenting preventive maintenance data, sites can examine it in conjunction with process and downtime data. Correlations may appear and help direct required maintenance and minimize downtime.

Provide Decision-Making Support to Operators

Since unplanned downtime is unavoidable, efforts should be made to reduce its duration. Operators who have access to tools and troubleshooting manuals in case of an outage can restart the process faster to minimize the impact of the downtime.

Operators must determine the reason behind the process’s initial failure in order to restart it. Giving operators the tools they need to identify the problem’s real cause is essential to a speedy resolution.

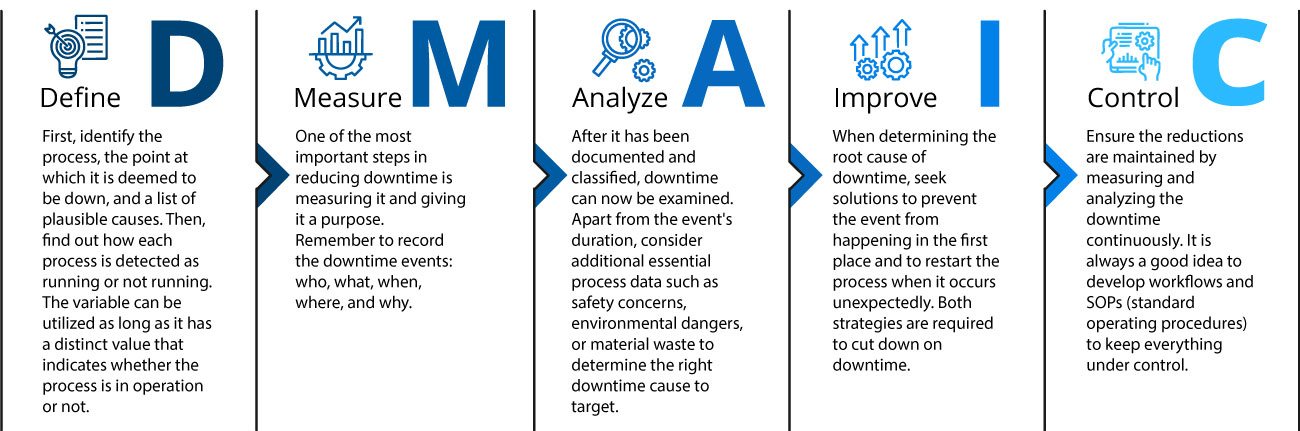

These are a few places to start when trying to reduce production downtime. The DMAIC method (Define, Measure, Analyze, Improve, Control) is an essential tool for lean manufacturing that can be used to save downtime.

In the manufacturing industry, “downtime” refers to when a machine or production line is not in use or malfunctioning, leading to a production stop. This downtime may occur unexpectedly due to unforeseen organizational problems or unanticipated maintenance or during periods when there are no orders.

The financial loss a business incurs during these unproductive times is known as the “cost of downtime.” It’s a significant outlay of money beyond the actual loss of productivity. It also covers incidental costs like labor costs for underutilized staff, reputational harm from missed deadlines, and even fines for late deliveries.

Each manufacturer’s unique set of conditions heavily influence the formula used to calculate downtime costs. Nonetheless, a more universal strategy might be expressed as follows:

Downtime Costs = Direct Cost + Indirect Cost

In this case, lost production value, squandered raw resources and repair costs are all considered as direct costs. Examples of indirect costs include missed sales opportunities, extra labor expenses, and reputational harm to a company. Considering this, the following would be a more intricate formula to calculate downtime cost:

Downtime cost = (Duration of downtime * Cost per minute of downtime) + (Lost revenue due to downtime) + (Cost of overtime) + (Cost of reputational damage)

It is important to remember that determining the precise cost of downtime can be challenging. Nonetheless, by applying the calculation formula mentioned above, you can obtain an approximate downtime expense and make sensible decisions regarding the mitigation of downtime risk.

Additional information regarding the downtime costs formula is provided below:

Although it isn’t possible to completely avoid downtime, manufacturers can take proactive measures to reduce the impact and frequency of unproductive events by being aware of the costs associated with them. Using real-time data is definitely one way to reduce downtime.

The actual cost of industrial downtime is a complicated topic with wide-ranging effects. The exact cost of production involves a range of direct and indirect expenses that can have a substantial impact on a manufacturer’s earnings, in addition to lost production time. In this fast-paced manufacturing world, manufacturers can preserve their competitive advantage and protect their operations by understanding these expenses and taking action to reduce downtime.

Different strategies and efforts are needed to reduce the unplanned costs of downtime; the key is to choose the appropriate tools and software for tracking and monitoring such unproductive events. Real-time data is required to prevent such events from happening in the future and to shorten production downtime.