The influence of technology on modern factory operations is significant, encompassing various advancements like autonomous mobile robots (AMRs), cloud computing, and 3D printing. Integrating these technologies leads to a more intelligent and adaptable manufacturing process, thereby bringing the concept of a Smart Factory Solution into practical fruition.

The smart factory concept pertains to an extensively digitized and interconnected environment wherein machinery and equipment enhance processes through automation and self-improvement. These smart factories are an integral aspect of the ongoing technological shift known as Industry 4.0, marking the current phase of the industrial revolution. These advantages extend beyond physical goods production, encompassing areas such as planning, supply chain, logistics, and even product development.

Nonetheless, the fundamental value proposition of smart manufacturing factories remains rooted within the confines of the manufacturing facility. A smart factory’s framework can comprise a blend of production, information, and communication technologies, with the potential for seamless integration spanning the entirety of the manufacturing supply chain.

All the disparate components of production can be interconnected via the Internet of Things (IoT) or other advanced integrated circuits (ICs), which facilitate the sensing, measurement, control, and communication of all activities occurring throughout the smart manufacturing process.

The prevalence of smart factory solutions is steadily increasing as business leaders acknowledge the imperative need for digital transformation within their supply chains to remain competitive and resilient. Concurrently, evolving consumer expectations are pivotal in propelling the development and swift adoption of smart factory technologies. According to industry reports, the third most challenging issue companies face is meeting customer demands for faster response times, necessitating increased investments in supply chain automation.

On the other hand, a smart manufacturing digital factory operates by seamlessly integrating machinery, personnel, and vast sets of Big Data into a unified, digitally connected ecosystem. Unlike its traditional counterpart, a smart factory doesn’t merely collect and analyze data; it actively learns from its experiences. It interprets and derives insights from data sets to predict trends and events and offers recommendations while executing intelligent manufacturing workflows and automated procedures. The smart factory continually refines its processes, autonomously correcting and optimizing itself—effectively teaching itself and its human counterparts to become more resilient, productive, and safe.

Numerous enterprises have been managing their supply chain operations and systems that have remained essentially unchanged for many years. However, given the heightened consumer expectations and the prevailing economic uncertainty, supply chain managers now require smart manufacturing solutions that can swiftly provide real and significant benefits. Reports suggest that only 43% of manufacturers had initiated smart factory projects. By 2019, this figure had risen to 68%. For companies willing to invest in digital transformation and the smart factory solution, the potential to realize significant business benefits exists. Some of these benefits are:

This results in advantages such as just-in-time inventory management, precise demand forecasting, and accelerated time-to-market, all contributing to enhanced efficiency. Furthermore, the insights provided by digital tools enable the workforce in smart manufacturing factories to streamline their tasks, further boosting overall productivity.

In a study on smart factories, companies observed improvements of up to 12% in areas like manufacturing output, factory utilization, and labor productivity after investing in smart factory initiatives. Additionally, it is projected that manufacturers with smart factories will likely outperform traditional factories with 30% higher net labor productivity by 2030.

Furthermore, the International Society of Automation highlights that robots and automated devices can play a pivotal role in reducing or eliminating three of the top five causes of workplace injuries.

The advanced analysis of system data promptly identifies weaknesses and opportunities for enhancement. As a result, this leads to increased competitiveness in the market, better product reviews, and reduced instances of costly returns or recalls.

Smart factory technologies exhibit remarkable agility. As a business intensifies its digital transformation endeavors, many opportunities exist to expand, alter, and adjust as required, offering virtually limitless possibilities.

Smart Factory is a full-stack, cloud-based solution combining MOM/MES/APS platforms for ultimate production control and efficiency. Smart Factory helps enterprises optimize their manufacturing processes and increase sustainability. It’s a solution that eliminates the necessity for manual systems, spreadsheets, and other dull and error-prone processes. With Smart Factory, you can optimize manufacturing, decrease expenses, and attain regulatory compliance. Smart Factory platform facilitates and empowers the “Industry 4.0” revolution.

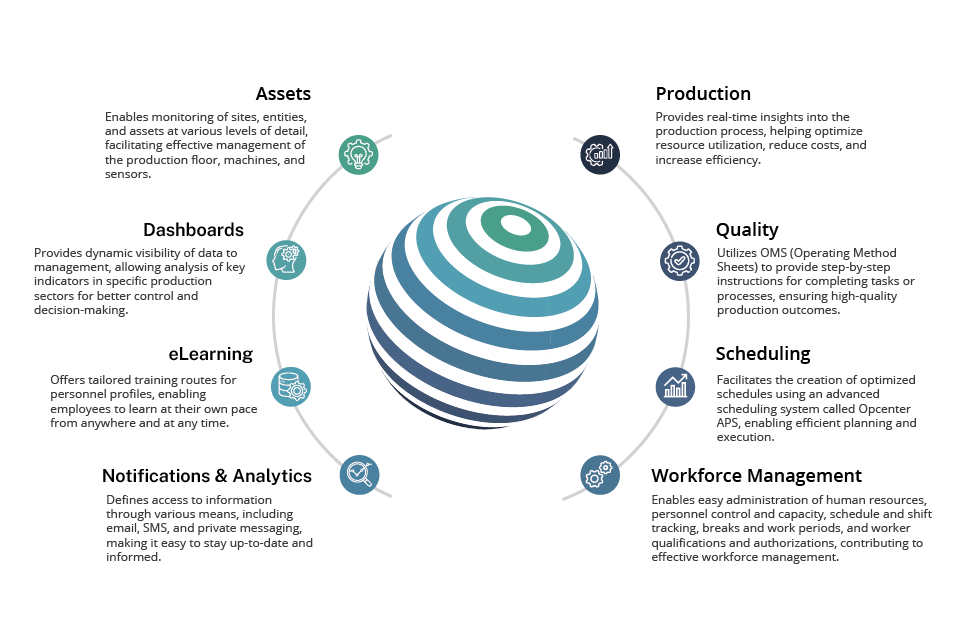

With four key capabilities, our platform offers a complete solution for manufacturers looking to enhance their operations:

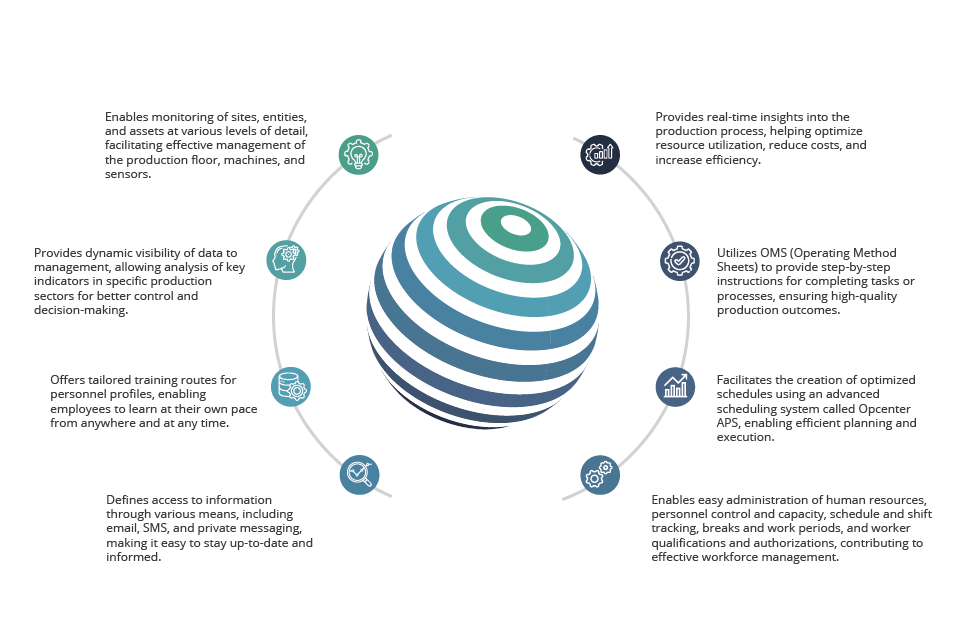

Smart Factory MOM for Manufacturers is an end-to-end solution encompassing Scheduling, Production, Asset Management, Training, Notification & Analytics, Quality Management, and Dashboards to help optimize the manufacturing workflow.

Each module can be selected as needed, giving you agile and quick deployment. Plus, our fixed-price implementation means you go live quickly without surprises.

When embarking on your digital transformation journey, it’s crucial to remember that a smart factory’s “smart” aspect stems from its advanced data analysis and data management capabilities. The core of a smart factory lies in a modern database and a robust ERP system, which provide the necessary support for the advanced functionalities that drive the entire system. A pivotal determinant of the success of a smart factory solution transformation lies in the ability of existing business systems to handle Big Data and seamlessly integrate technologies like machine learning and advanced analytics.

Moreover, smart factory transformation is beneficial because it doesn’t have to be a sudden, all-encompassing change. It doesn’t necessitate the interruption or pause of existing business operations. Each step a business takes to modernize and optimize its digital systems brings it closer to achieving a fully integrated smart factory. Furthermore, smart factory manufacturing technologies inherently collect and analyze data, enabling the immediate measurement and assessment of any newly implemented digital technologies’ impact and return on investment (ROI) from the moment they are deployed.