The manufacturing industry has been experiencing a significant transformation in recent years, driven by the emergence of Industry 4.0. Industry 4.0 is the fourth industrial revolution and is characterized by the integration of digital technologies and advanced automation to create smart, connected manufacturing facilities. This integration enables real-time communication, remote monitoring, and data collection, providing manufacturers with unprecedented advances in quality, reliability, and agility.

One of the key benefits of Industry 4.0 is that it makes existing tools, such as ERP (Enterprise Resource Management) and Manufacturing Execution System (MES) more powerful than ever before. This leads to process control optimization, more effective and proactive production activities, and the flexibility for personnel to perform their tasks from anywhere. Industry 4.0 technologies allows for more agile and responsive operations, with the ability to adapt to changing market conditions and customer demands.

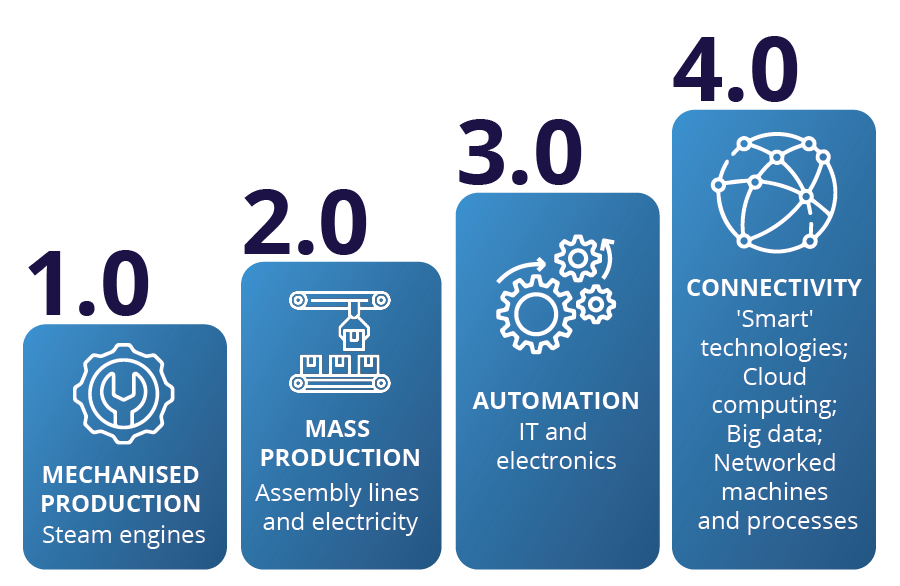

Industry Revolution History

The history of the industrial revolution spans over centuries, with each period marked by significant technological advancements.

1. Industry 1.0

The first industrial revolution, also known as Industry 1.0, began in the 18th century with the introduction of machine-based production, which replaced manual labor with steam-powered machines. This led to an increase in productivity, growth of factories, and mass production.

2. Industry 2.0

In the late 19th and early 20th centuries, the second industrial revolution, or Industry 2.0, was triggered by the development of electricity and the internal combustion engine. This period saw the widespread use of steel and concrete in construction, and Henry Ford played a significant role in setting a high productivity standard for the automotive industry. Chemical manufacturing also increased its productivity at a lower cost during this period.

3. Industry 3.0

The third industrial revolution, or Industry 3.0, began in the late 20th century with the digital revolution. The development of computers, memory-programmable controls, and the internet marked this period. Automation started being used in production processes, with robots performing programmed sequences without human intervention.

4. Industry 4.0

Industry 4.0 is the current period of technological development and refers to the fourth industrial revolution. This revolution is characterized by the integration of advanced technologies such as artificial intelligence (AI), machine learning, the Internet of Things (IoT), and robotics into industrial processes. Industry 4.0 creates “smart factories” that are highly automated, data-driven, and fully connected to supply chains. This revolution has significantly increased efficiency and productivity in manufacturing operations, and implementing a structured, agile, and collaborative approach has become increasingly important.

Technologies that Support Industry 4.0

Industry 4.0 has been made possible by the emergence of several technologies that have transformed traditional manufacturing operations. These technologies are designed to enable faster decision-making, improve efficiency, and increase productivity in industrial sectors. Here are some of the leading technologies that support Industry 4.0:

1. Artificial Intelligence

AI has been a game-changer in manufacturing operations, allowing computer systems to perform tasks that previously required human intelligence. Manufacturers use AI for predicting equipment failures, adapting maintenance plans accordingly, performing quality control inspections, and managing supply chain issues. By using AI in manufacturing, manufacturers can reduce costs, improve accuracy, and optimize operations.

2. The Internet of Things

IoT technology interconnects physical devices using the internet, such as sensors and actuators, and is used for real-time monitoring by collecting and transmitting data from equipment and machines. The IoT enables manufacturers to gather and analyze data from a wide range of sources, improving decision-making processes and leading to better outcomes.

Want to leverage the power of IoT technology in your factory? Discover how Smart Factory MOM can provide you with real-time insights and analytics, improving your factory’s performance and profitability.

3. Cloud Computing

Cloud computing allows for the delivery of computing services and storage over the internet, enabling the analysis of large amounts of data. By using cloud computing, manufacturers can analyze data in real-time, which can be used to reduce decision-making time and improve operational efficiency.

4. Big Data and Analytics

Big data and analytics allow manufacturers to analyze large volumes of data from different equipment, devices, and sensors. This helps to identify trends and patterns in data, giving better insight into specific situations or problems. Big data and analytics are often used in manufacturing operations to identify correlations between variables that affect a production process.

5. Augmented Reality (AR), Virtual Reality (VR), and Mixed Reality (MR)

AR, VR, and MR are a set of technologies that combine real and virtual environments and human-machine interactions generated by computer technology. This technology is used in industrial sectors to improve training and visualization of manufacturing or maintenance processes. It can greatly improve the employee training and contribute significantly to performing manual tasks remotely.

6. Additive Manufacturing (3D printing)

Additive manufacturing is the process of building 3D objects layer by layer from a digital file. This technology is widely used in product design stages to develop prototypes or, in the execution stage, to create custom parts without having large volumes of inventory. Additive manufacturing enables manufacturers to produce parts with complex geometries that cannot be achieved using traditional manufacturing methods.

What is Changing with Industrial Revolution 4.0?

Industry 4.0 is revolutionizing the manufacturing industry, with the integration of advanced technologies and principles that enable a smarter and more efficient production process. The changes brought about by Industry 4.0 are significant and can be broadly categorized into the following areas:

1. Data monitoring and collection through sensors

One of the key components of Industry 4.0 is the use of sensors that enable real-time monitoring and data collection from every piece of equipment in a facility. This data is then analyzed to provide valuable insights for decision-making related to maintenance, process control, inventory management, and personnel management. Older machinery can be upgraded to work with sensors to take advantage of data monitoring benefits.

2. Expanded communication between equipment and systems

Industry 4.0 has creation a fully interconnected facility where all equipment feeds data into software systems. This enables more informed decision-making at macro and micro levels, resulting in increased efficiency, safety, and productivity. With the widespread adoption of 5G technology, networking technology will play an even greater role in the effects of Industry 4.0.

3. More advanced automation

While automation is not new to the manufacturing industry, Industry 4.0 takes automation technology even further. This technology enables more informed programming, innovative ways for people and robots to work together, and overall efficiency, safety, and productivity.

4. Data analytics and action

The massive amount of data collected in real-time through sensors and other monitoring technologies allows for more effective process control through fine-tuning and adjustment. Industry 4.0 also brings about more reliability-centered production, including predictive production that reduces downtime, increases productivity, and keeps shop floors operating at peak performance.

Industry 4.0 for Small and Medium-sized Enterprises (SMEs)

Industry 4.0 is not only transforming the manufacturing industry but also revolutionizing the way SMEs operate. Although SMEs may face resource constraints and have limited access to sophisticated technologies, they can leverage Industry 4.0 concepts to gain a competitive advantage.

One of the most significant benefits of Industry 4.0 for SMEs is increasing efficiency and reducing costs through automation and data analysis. Automation can help SMEs optimize their production lines and minimize manufacturing downtime, while data analysis can provide insights to improve decision-making, reduce waste, and increase overall efficiency. SMEs can reduce operational costs and improve the quality of their products and services by utilizing Industry 4.0 technologies such as the Internet of Things (IoT), cloud computing, and artificial intelligence (AI). Moreover, Industry 4.0 can help SMEs achieve greater flexibility and responsiveness to market demands.

Challenges for SMEs to Invest in Industry 4.0 Technologies

Industry 4.0 has brought revolutionary changes to the manufacturing industry. It has enabled manufacturers to increase their efficiency, productivity, and accuracy, while reducing downtime and errors. However, SMEs often face several challenges with these new technologies. Some of the most significant challenges SMEs face in Industry 4.0 are:

1. Cybersecurity

As SMEs increasingly rely on digital technologies, they become more vulnerable to cyber-attacks. Many SMEs lack the resources to invest in comprehensive cybersecurity measures, making them particularly vulnerable to data breaches, ransomware attacks, and other cybersecurity threats.

2. Workforce training

The rapid pace of technological change in Industry 4.0 requires SMEs to invest in employee training to keep their workforce up-to-date with the latest technologies. However, many SMEs may not have the resources to provide this type of training.

3. Data management

With the increase in digital data generated by Industry 4.0 technologies, SMEs need to invest in data management solutions to store, analyze, and utilize this data effectively. However, many SMEs may not have the resources or expertise to manage this data.

4. Integrating new technologies

Integrating new technologies into existing operations can challenge SMEs. This requires investment in new equipment, software, and training, which may be costly and time-consuming.

5. Supply chain management

Industry 4.0 technologies can enable greater supply chain visibility and efficiency. However, SMEs may struggle to implement these technologies due to a lack of resources or collaboration with other businesses in the supply chain.

How Smart Factory Manufacturing Operations Management (MOM) Fits into the Industrial Revolution 4.0?

As we have seen, Industry 4.0 is transforming the manufacturing industry by leveraging technologies such as AI, IoT, big data, and automation to drive efficiency, productivity, and innovation. Smart Factory MOM is a critical component of industry 4.0, as it enables manufacturers to collect, analyze, and act upon data in real-time across the entire production process.

Smart Factory MOM integrates data from various sources, including sensors, machines, and human operators, to provide real-time visibility and control over production operations. This enables manufacturers to optimize production efficiency, reduce downtime, and improve quality by identifying and addressing issues before they become problems.

The Smart Factory solution is a critical component of Industry 4.0, providing manufacturers with the necessary tools to achieve digital transformation and optimize their manufacturing processes. Here are some of the ways in which Smart Factory MOM fits into the industrial revolution 4.0:

1. Cloud-based solution

Smart Factory MOM offers a cloud-based solution that provides manufacturing organizations of all sizes and locations with greater adaptability, flexibility, scalability, and data protection.

2. Utilizes IoT, machine learning, and predictive analytics

Smart Factory MOM incorporates advanced technologies like the IoT, machine learning, and predictive analytics to optimize and improve manufacturing performance. These technologies enable manufacturers to collect, analyze, and act on data in real-time, improving decision-making and enhancing operational efficiency.

3. Effective scheduling of resources

Smart Factory MOM utilizes a Siemens-powered advanced planning and scheduling (APS) engine to provide effective scheduling of resources. This ensures that resources are utilized optimally and efficiently, increasing productivity and reducing downtime.

4. Real-time data collection and tracking

Smart Factory MOM allows for real-time data collection and tracking of employees, equipment, and work orders. This ensures that the manufacturing process is monitored and controlled in real-time, providing manufacturers with complete visibility into their operations.

5. Automatic data capture

Smart Factory can automate data capture from machines and other devices, providing seamless connectivity for Industry 4.0. This eliminates the need for manual data entry, reducing errors and improving efficiency.

6. World-class factory performance analysis

Smart Factory provides out-of-the-box, world-class factory performance analysis with loss visualization. This helps manufacturers gain instant insight into their manufacturing operations, enabling them to identify areas for improvement and implement changes quickly.

7. Paperless shop floor

Smart Factory enables a paperless shop floor with downtime alerts and collaborative messaging, helping to minimize waste and streamline processes. This results in a more efficient and sustainable manufacturing process.

8. Applicable to multiple industries

Smart Factory is highly configurable and applicable for any industry, including automotive, aerospace, electronics, medical devices, consumer products, and more. It offers flexible solutions to meet the unique needs of each industry, providing anytime access through sophisticated, next-generation web-based technologies.

Smart Factory MOM for SMEs

Smart Factory MOM is a modular system that provides a comprehensive solution for managing and optimizing manufacturing operations. It leverages cutting-edge technologies like IoT, AI, and data analytics to enable real-time monitoring, analysis, and control of all aspects of the production process. This makes it an ideal solution for small and medium-sized enterprises (SMEs) looking to use Industry 4.0 technologies to improve their operations and compete in an increasingly digital and connected market.

Smart Factory MOM can be a great solution for SMEs in manufacturing because of the following reasons:

| Smart Factory Benefit | Explanation |

|---|---|

| Scalable Solution | Smart Factory MOM is a modular and scalable solution, which means that SMEs can start with the modules that are most relevant to their needs and then add more modules as their business grows. This helps SMEs avoid high upfront costs and only pay for the needed features. |

| Real-Time Data Analysis | Smart Factory MOM collects real-time data from various manufacturing processes, which allows SMEs to gain insights into their production performance. This can help SMEs to identify areas for improvement and optimize their manufacturing processes to increase efficiency and reduce costs. |

| Better Resource Allocation | Smart Factory MOM helps SMEs to manage their resources more efficiently by providing real-time information on the status of machines, materials, and personnel. This can help SMEs make better resource allocation decisions and reduce downtime. |

| Integration with Existing Systems | Smart Factory MOM can integrate with existing ERP, PLM, and CRM systems. This means that SMEs can avoid needing expensive and time-consuming system replacements and instead enhance their existing systems with new features and capabilities. |

| Increased Transparency | Smart Factory MOM provides increased transparency into manufacturing processes, which can help SMEs to meet compliance requirements and reduce the risk of quality issues or recalls. |

Take a step towards smarter manufacturing today. Book a demo of Smart Factory MOM and discover how our solution can improve your factory’s efficiency, reduce downtime, and increase profitability.

Functionalities of Smart Factory MOM

Smart Factory MOM comes equipped with numerous features and functionalities that make it the most obvious choice for SMEs in the manufacturing industry. Some of its incredible features and functionalities include:

1. Manufacturing Execution System/Suite (MES)

The MES capabilities in Smart Factory track and document the transformation of raw materials into finished goods, providing real-time production management to drive enterprise-wide compliance, quality, and efficiency.

2. Advanced Scheduling

It uses a constraint-based strategic approach to generate schedules that consider all scheduling requirements and objectives in an integrated and computerized manner.

3. Production Monitoring

Production monitoring enables seamless connection to machines on the factory floor, provides clear and up-to-date operational key performance indicators (KPIs) and dashboards, and facilitates ongoing enhancements in manufacturing processes.

4. Asset Performance Management

It combines process, operational, and machine-level data through dashboards to monitor machine and plant health, ensuring optimal uptime, throughput, and maintenance.

5. Operating Method Sheets (OMS)

The OMS feature in Smart Factory standardizes and automates quality documentation, processes, and measurements.

6. Real-time Data Sync

Smart Factory MOM enables real-time data sync by connecting with self-aware and system-aware assets. These assets can acquire and process operating data, monitor and report on asset conditions such as self-diagnostics and energy usage, and provide real-time information to optimize production processes.

7. Staff Management

It enables easy administration of human resources, personnel control and capacity, schedule and shift tracking, breaks and work periods, and worker qualifications and authorizations.

8. Real-Time Analytics

It provides easy and dynamic data visibility to management, enabling control and analysis of key indicators in specific production sectors.

9. Instant Notifications for Effective Communication

It provides instant notifications for various reasons related to productivity, maintenance, production monitoring, or quality.

10. Easy-to-Access Training

It provides tailored training routes for personnel profiles, enabling employees to learn at their own pace from anywhere and anytime.

Wrapping up

Industry 4.0 is transforming the manufacturing industry in unprecedented ways, and Smart Factory MOM is at the forefront of this transformation. With its cloud-based solutions, advanced technologies, effective scheduling of resources, and world-class performance analysis, Smart Factory MOM provides manufacturers with the tools they need to achieve their production goals, reduce waste, and increase profitability. As manufacturers continue to adapt to this new paradigm, Smart Factory MOM will undoubtedly play an increasingly important role in driving the industry forward into the future.