Crafting the perfect balance between operational efficiency and product quality is the shared aspiration of manufacturers across industries. At Smart Factory MOM, we understand the importance of this pursuit, which is why we have developed the Smart Factory MOM solution – a cutting-edge approach to overseeing and optimizing the production process.

MOM, an abbreviation for manufacturing operations management, encompasses an array of strategies, practices, and cutting-edge technologies aimed at streamlining and enhancing manufacturing operations. It entails harmonizing and controlling multiple elements within the production environment, including personnel, machinery, materials, and information.

Our comprehensive guide will take you on an exploration of the fundamental facets of manufacturing operations management. Together, we will delve into its significance, explore effective strategies, uncover best practices, and unravel the potential of our innovative Smart Factory MOM solution. It’s tailor-made for forward-thinking manufacturers keen on embracing the limitless power of digital transformation.

Whether you are a seasoned manufacturing professional striving to augment your expertise or a visionary business leader in search of ways to optimize your operations, this manufacturing operations management 101 guide will furnish you with invaluable insights and actionable guidance, enabling you to navigate the realm of MOM with finesse.

Now, let us embark on this transformative journey together, unraveling the boundless possibilities offered by manufacturing operations management.

Manufacturing operations management is an integrated framework of systems and practices designed to optimize end-to-end manufacturing processes. It involves efficiently managing various business resources, including personnel, technology, equipment, and other assets that contribute to the manufacturer’s productivity and efficiency.

At its essence, MOM ensures a seamless synchronization between the physical equipment and the user interface within a business environment. It establishes a cohesive platform where human and automated activities are seamlessly integrated in real-time, fostering a harmonious collaboration between operators and machines.

The overarching goal of manufacturing operations management is to enable informed decision-making, streamline operations, and uphold superior quality management throughout the manufacturing lifecycle.

Manufacturing and service operations management is a critical aspect of the manufacturing industry. Whether we are discussing processes or software, the purpose of manufacturing operations management is to enable continuous improvement within the manufacturing environment. It plays a key role in determining the effectiveness of operations management across various areas, including inventory management, production, quality control, maintenance, and lean manufacturing operations management.

Efficient inventory planning and monitoring are vital to prevent disruptions in production caused by raw material shortages. With proper inventory management, a factory can avoid grinding to a halt. Similarly, production needs to be carefully planned, controlled, and analyzed to ensure smooth operations. Monitoring machines and SCADA systems are essential for maintaining optimal performance. Moreover, monitoring quality is essential for customer satisfaction, while proper maintenance planning, execution, and monitoring are necessary to keep everything running smoothly.

With the increasing complexity of manufacturing operations and the vast amounts of data collected and processed by companies, automating manufacturing operations management becomes helpful and necessary to keep up with the fast-paced manufacturing industry.

Disconnected and isolated business units can lead to production delays and wasted resources due to misaligned supply chain management. For instance, when a production process changes, obtaining approvals, conducting tests, documenting modifications, and reporting them are crucial steps. Access to the most up-to-date data is essential for the people involved to swiftly implement the necessary changes, distribute documentation, and report updates, thus avoiding prolonged production delays.

Before we delve into the benefits of MOM, it’s essential to take a step back and recognize the necessity of smart factories and the manufacturing industry’s digital transformation. The infographic below highlights notable trends, challenges faced by manufacturers, and key priorities that must be addressed to align with the goal of digital transformation.

Now, let’s view some of the benefits of MOM or lean manufacturing operations management that make it more significant from a perspective of smart manufacturing:

Developing an effective manufacturing operations management strategy is essential for optimizing manufacturing operations and achieving overall efficiency. Here are some key goals to consider when developing a manufacturing operations management strategy for your company.

Implementing best practices in manufacturing operations is crucial for achieving efficiency, productivity, and continuous improvement. These practices, including those derived from lean manufacturing operations management principles, help organizations optimize operations and drive success.

By incorporating these best practices, organizations can create a foundation for continuous improvement, optimize manufacturing operations, and achieve sustainable growth in an increasingly competitive market.

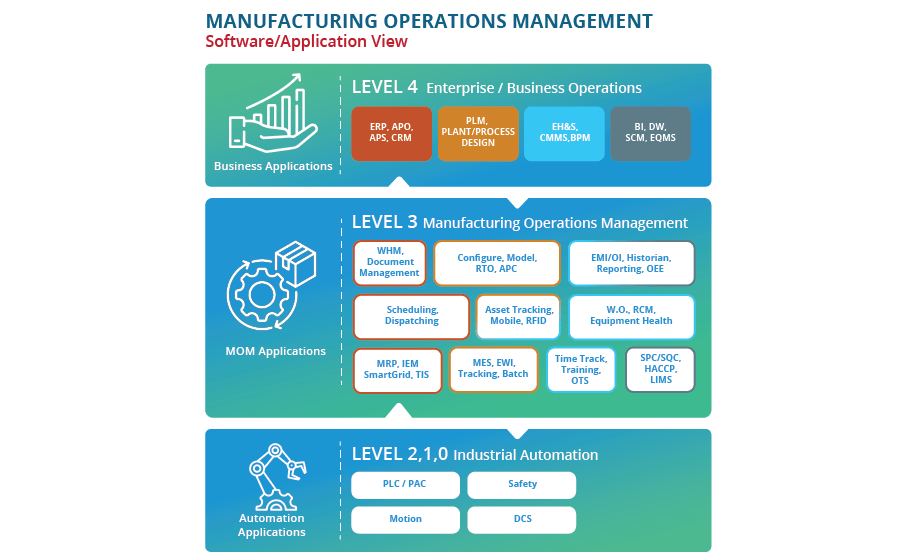

The graphic below accurately illustrates a typical manufacturing landscape, showcasing different applications and tools at various levels, including manufacturing operations management applications that are instrumental in the digital transformation of a manufacturing organization.

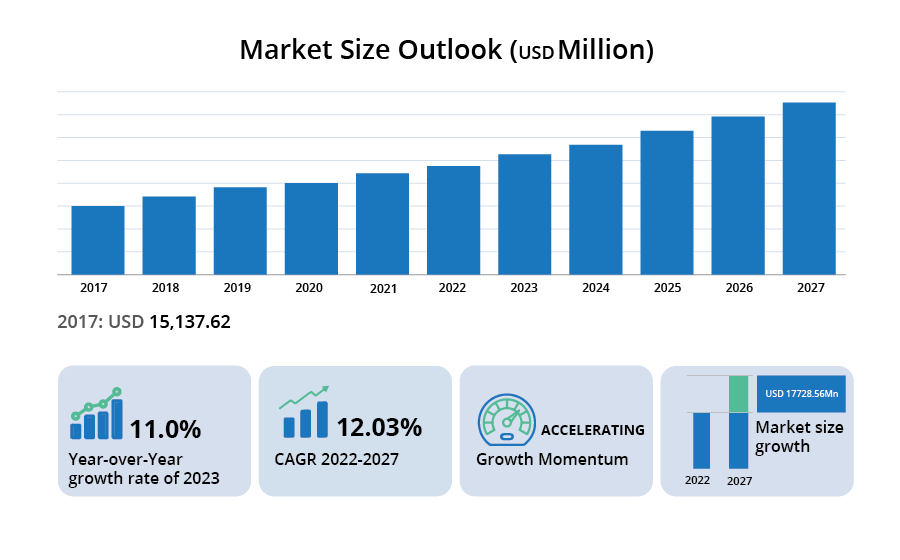

The manufacturing operations management software market is experiencing significant growth, with an estimated CAGR of 12.03% between 2022 and 2027. The market size is projected to increase by USD 17,728.56 million.

The increasing demand for automation in industrial sectors is a prominent driver of market growth. As industries strive for improved efficiency and productivity, adopting and developing software-based solutions like MOM have gained traction. MOM software facilitates the flow of information from the shop floor, provides better visibility, and enables real-time control and adjustments to operations. With real-time metrics, load patterns, production requirements, and resource demands can be analyzed for energy savings. These factors positively impact market growth by enhancing operational efficiency and productivity.

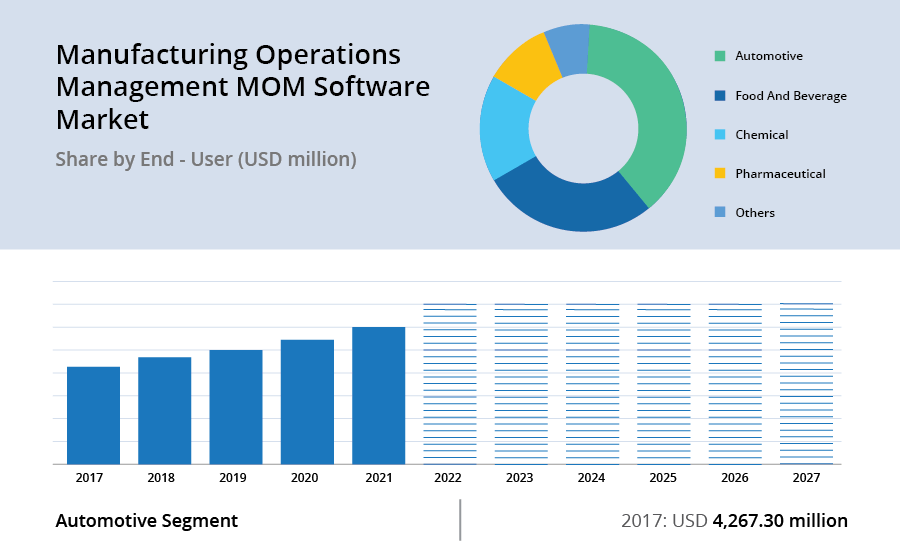

The automotive segment is poised for significant growth in the manufacturing operations management software market. As one of the fastest-growing industries and a significant contributor to the manufacturing sector, the automotive industry encompasses the manufacturing of chassis for automobiles and light-duty motor vehicles and the assembly of final automotive and light-duty motor vehicles. This includes a range of vehicles such as cars, cross utility vehicles (CUVs), sport utility vehicles (SUVs), pickup trucks, and vans.

The automotive segment has demonstrated steady growth, with a valuation of USD 4,267.30 million in 2017 and continued growth until 2021. Digitization of manufacturing processes is crucial in enabling efficient production within the automotive industry. By embracing digitization, automotive players can explore monetizing opportunities at the consumer end while transforming workplaces through robotics and automation. This shift towards a digitized workplace is pivotal in gaining a significant competitive edge in the automotive sector.

MOM software addresses the industry-specific challenges the automotive sector faces, including the need for enhanced connectivity and mobility in manufacturing processes to optimize manufacturing time and equipment utilization. The increasing demand for value extraction from data and advanced connectivity across the value chain profoundly impact the entire automotive industry ecosystem. Consequently, it serves as a critical driver for adopting MOM software in the automotive sector.

Smart Factory MOM solution offers comprehensive features and capabilities to transform your manufacturing operations and gain a competitive edge in today’s market. With its advanced functionalities, Smart Factory MOM enables end-to-end manufacturing lifecycle management, empowering you to optimize and enhance your production processes.

Here are the key highlights of Smart Factory MOM solution:

At Smart Factory MOM, we are dedicated to helping manufacturers transform their operations and achieve new levels of efficiency. Our cutting-edge Smart Factory MOM Solution seamlessly integrates scheduling, production management, resource management, training, analytics, and quality management activities into a unified platform. By leveraging our solution, manufacturers can streamline workflow, optimize resource utilization, and drive lean manufacturing operations management.

With Smart Factory MOM, you gain a 360-degree view of your production processes, accessing real-time insights that empower informed decision-making. Our solution enables efficient monitoring and control, leading to enhanced operational performance and adopting lean manufacturing practices.

Take the next step towards optimizing your manufacturing operations and embrace the future of manufacturing and service operations management with Smart Factory MOM solution. Contact us today to learn how our solution can revolutionize your operations and drive your success in the digital age.